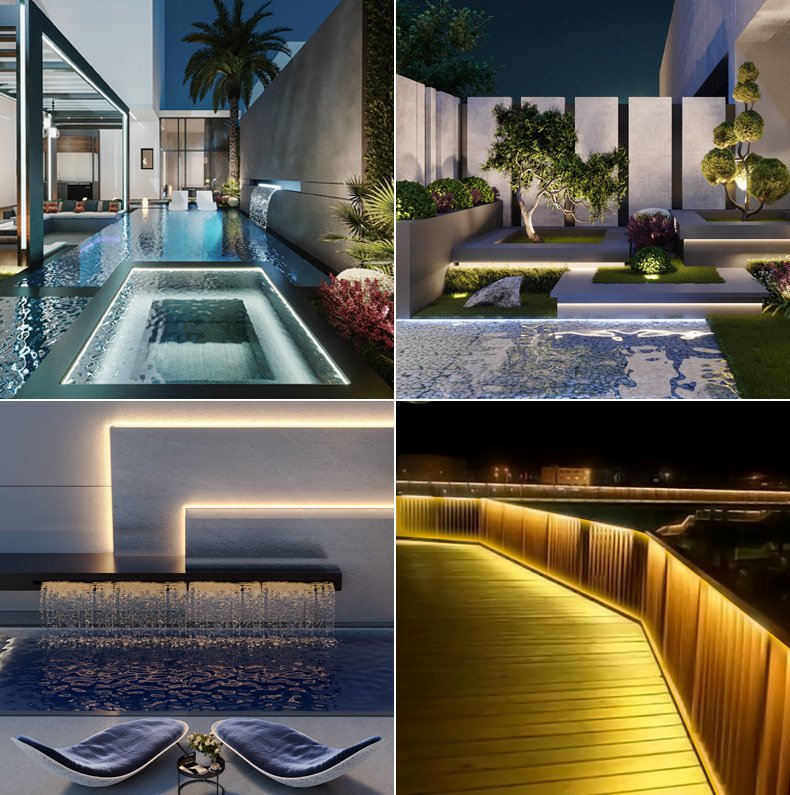

We know that in the process of social development, the development of urban construction has become increasingly important. In the dark night, lights take on even greater significance. But how can we keep the lights shining all the time? At this moment, the high-voltage light strips are of great significance.

The light strips usually come in 1 row, 2 rows, or 3 rows. So, what are the differences and advantages among them?

| Characteristics | 1 Row | 2 Rows | 3 Rows |

| Structure | There is only one row of LED chips, arranged uniformly | Two rows of LED chips, usually arranged alternately. | Three-row LED chips, with higher density. |

| Brightness | Standard brightness, suitable for basic lighting and creating an atmosphere. | Main area’s basic lighting (such as ceiling lighting), required for brighter and more uniform scenes. | Ultra-high brightness, the light is very rich and full, approaching a uniform light band. |

| Light uniformity | There is a distinct “granular” or “light spot” effect, where individual light bulbs can be seen. | The graininess is significantly reduced, and the light is more continuous and gentle. | Almost no graininess, the light is uniform like flowing water, with a high-grade texture. |

| Power and Heat | Medium power, with attention needed on heat dissipation. | Medium power, attention should be paid to heat dissipation. | High power, high heat generation, it needs to be cooled by an aluminum trough. |

| Application Scenarios | Main area’s basic lighting (such as ceiling lighting), required for brighter and more uniform scenes. | The basic lighting in the main area (such as ceiling) and scenarios requiring brighter and more uniform light. | Commercial lighting, exhibition halls, and main lighting for high-end home decoration and luxurious decoration with extremely high requirements for light uniformity. |

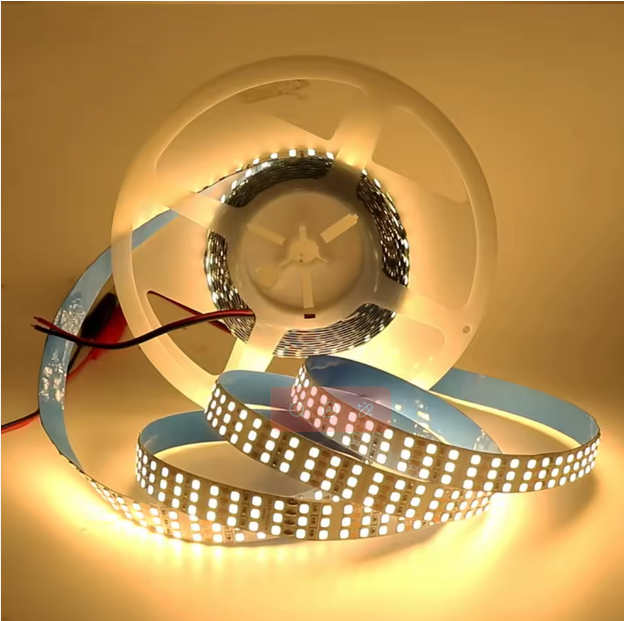

Types of high-voltage LED light strips —->SMD 2835 AC220V/110V 120LEDs/m

The 10V/220V high-voltage LED strip lights have been widely used in various fields due to their numerous practical advantages. Among them, the driverless LED strip lights stand out particularly. SMD and COB LED strip lights are the most common types, and each type has its own unique functions and lighting performance, suitable for different needs.

SMD LED light strips are currently the most common high-voltage LED lighting products. They use LED chips such as SMD2835 or SMD5050 and install them on flexible circuit boards. SMD light strips are renowned for their high brightness and wide beam angle, making them ideal choices for outdoor signs, building outlines, and indoor accent lighting.

Key Features of the 220V SMD2835 120LED Strip Light

- High LED Density: 120 LEDs per meter ensure consistent, dot-free illumination.

- Direct 220V Input: Plug-and-play functionality without transformers.

- Cuttable Design: Can be cut every 10 cm to meet exact project requirements.

- Self-Adhesive Backing: Strong glue layer ensures easy installation on smooth surfaces.

- Upgraded Build: Enhanced stability and brightness compared to traditional single-row strips.

- Multiple Colors and Temperatures: Options include white (6000–6500K), warm white (2700–3000K), neutral white (4000–4500K), cool light (8000–10000K), red, green, blue, pink, and icy blue.

- Flexible Construction: Can bend around curves and corners for creative layouts.

- Durable Protection: Available in IP20 (indoor), IP65, and IP67 ratings for wet or outdoor environments.

- Long Lifespan: Over 50,000 hours of reliable performance.

When choosing the light strips, you should not only consider the number of rows, but also pay attention to these key parameters.

Chip quality and brand: Brands such as Cree, Seoul Semiconductor, and Pryor have more stable chips and better light efficiency.

Color rendering index: You must choose Raz90. The higher the better, as it provides more realistic color reproduction.

Color temperature: Commonly used values are 3000K (warm yellow), 4000K (neutral light), and 6000K (cold white). Choose according to your style.

Number of light beads per meter: For example, single row has 60 beads per meter, while double row may have 120 beads per meter. The density also affects uniformity.

Whether there is a controller: If you need to adjust the light and color, you need to pair it with the corresponding driver and control board.

To sum up:

One row is sufficient, two rows are practical, and three rows aim for the ultimate. For most modern home decorations, choosing a light strip solution with two rows, high luminance index, and aluminum channel installation is the safest and most outstanding choice for creating comfortable and high-end indoor lighting.

Exsun Light, as a professional light strip manufacturing company, will provide you with more effective suggestions, allowing you to save more time and costs.

Phone:+86 15819498823

Email: Janny@exsunlighting.com

WhatsApp:+861331826846